Graphite Brush Wear Sensor

Development of equipment for measuring, recording, and alerting wear of graphite brushes in direct current motors for mining equipment with high operational criticality (2015)

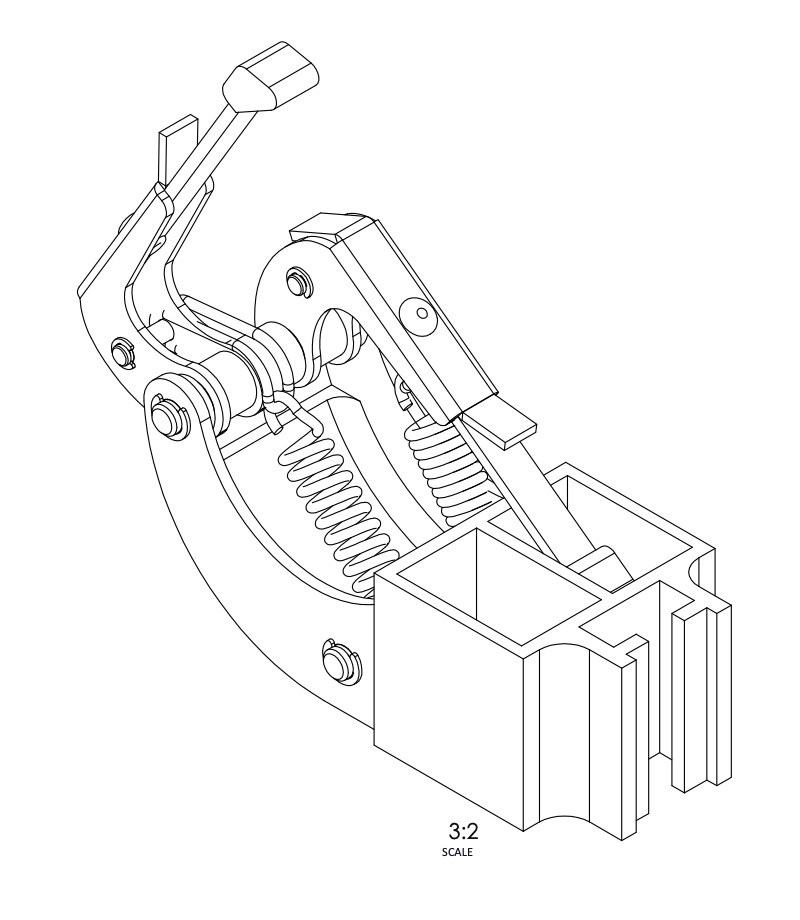

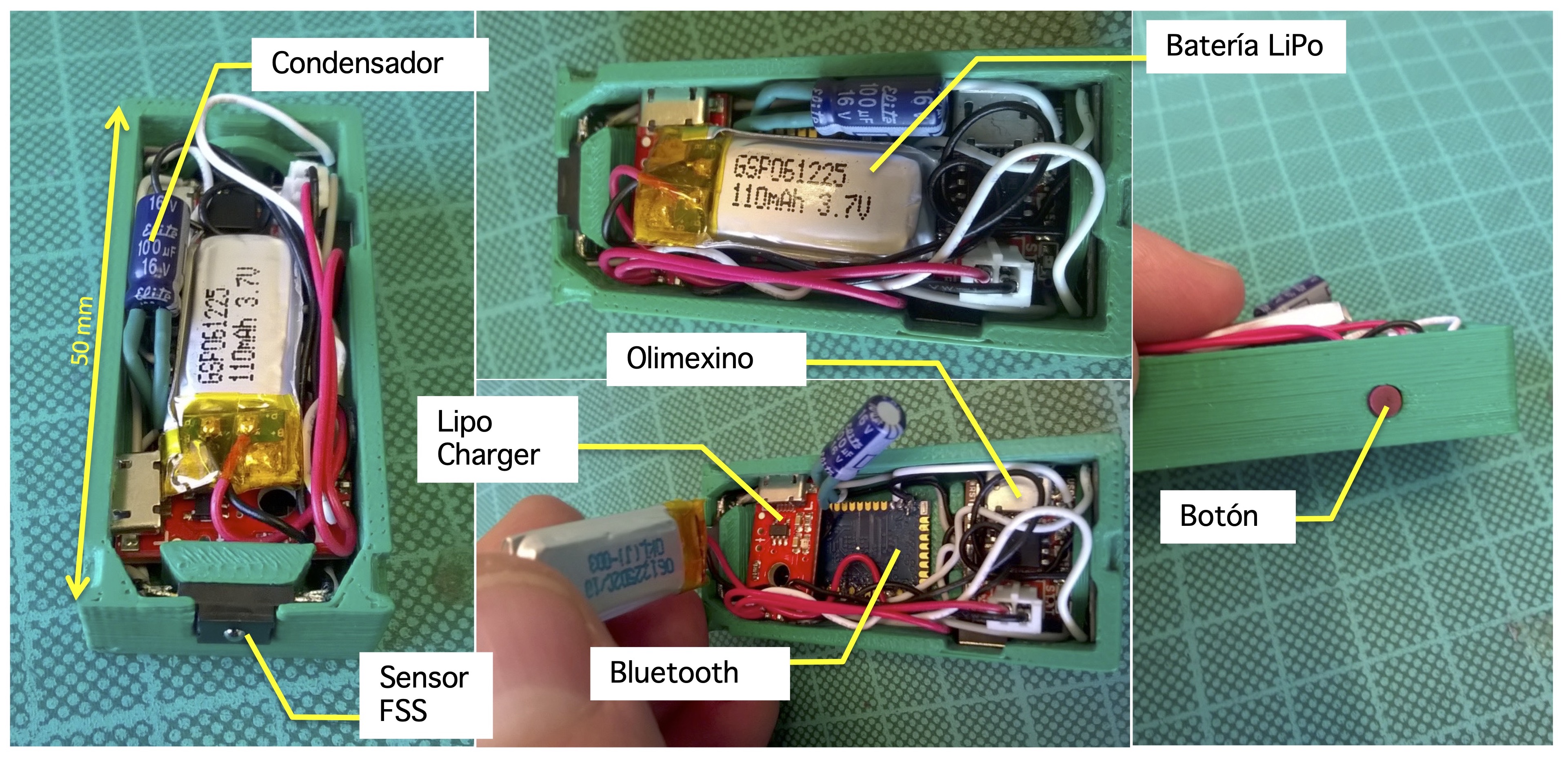

InnovaChile (Voucher) (2015), Company Prodin SPA Role: IT engineer designer / developer ($14k USD). The project focuses on developing an instrument for measuring and recording operating parameters and wear control of graphite brushes in direct current motors, belonging to critical equipment in mining operations, such as: loading shovels and SAG mills. This instrument will record the length of the graphite brush and the pressure of its spring measured in-situ, relating them to the manufacturer’s recommendations, providing as a response whether it is necessary to change these elements or not.

Cite: (Carrasco et al., 2019).